Acumatica Material Requirements Planning

Time-phased material planning ensures materials are procured or manufactured just in time. Critical material reports and exception messages help planners respond to real-world changes impacting demand and production schedules.

• Drive material requirements plans from the Master Production Schedule (MPS).

• Identify critical materials and manage plans by exception.

• Run MRP for actual and forecasted material demand.

Generate time-phased manufacturing and purchasing plans for optimal inventory availability tied to forecast and customer demands. Reduce inventory, improve customer service, and avoid shortages and stock-out scenarios that result in costly changeovers and rush orders.

MRP enables companies to set and maintain stock levels for frequently used items with a consolidated view of demand in user-defined time buckets with recommended actions to manage shifts in supply and demand.

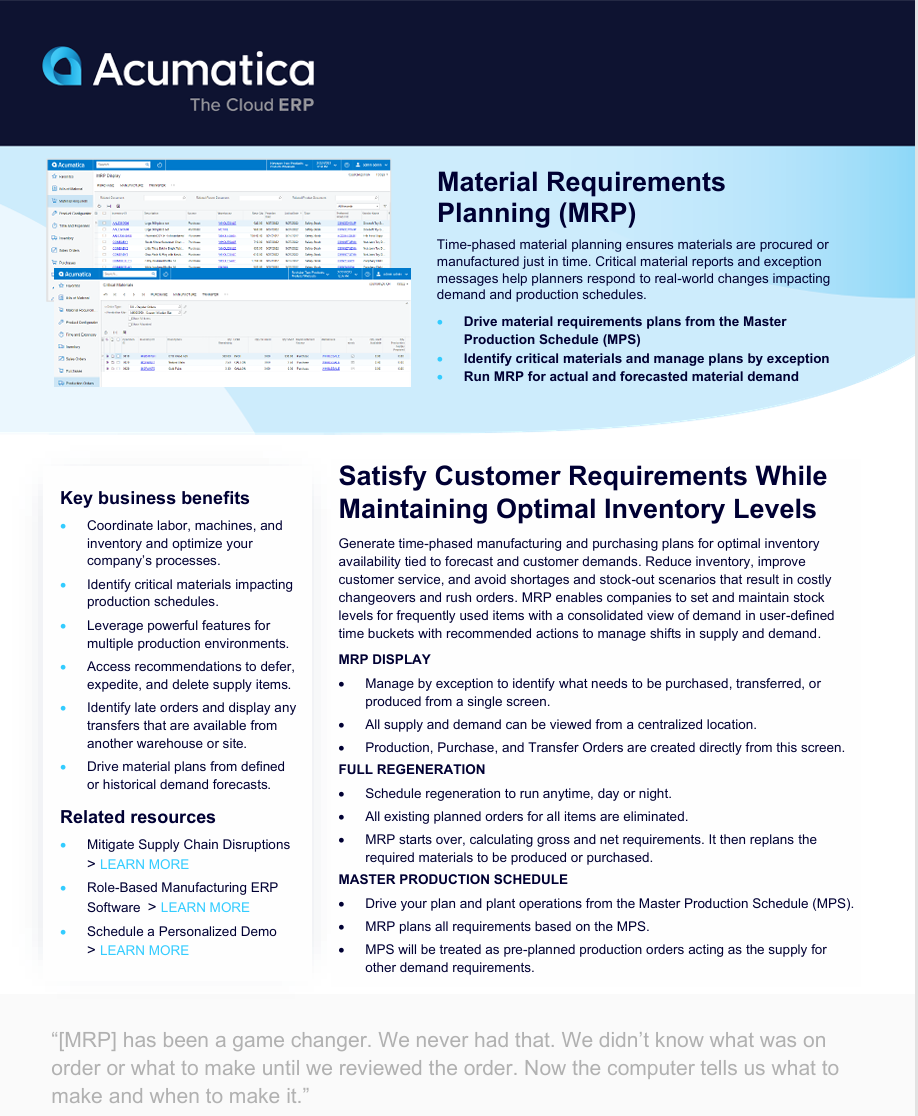

MRP DISPLAY

• Manage by exception to identify what needs to be purchased, transferred, or produced from a single screen.

• All supply and demand can be viewed from a centralized location.

• Production, Purchase, and Transfer Orders are created directly from this screen.

FULL REGENERATION

• Schedule regeneration to run anytime, day or night.

• All existing planned orders for all items are eliminated.

• MRP starts over, calculating gross and net requirements. It then replans the required materials to be produced or purchased.

MASTER PRODUCTION SCHEDULE

• Drive your plan and plant operations from the MPS.

• MRP plans all requirements based on the MPS.

• MPS will be treated as pre-planned production orders, acting as the supply for other demand requirements.